Merchant information

| 53 Ubi Avenue 1 #01-01 Paya Ubi Industrial Park S(408934)

( 1 more outlet ) |

||

| 9.30am - 7.30pm (Mon - Sat) | ||

|

68444281

98457540 |

Ad information

››› Appearance test

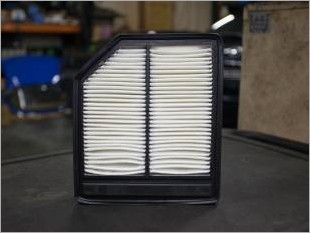

Maximized space utilization with 3D design. Tailored through each car, making full use of the limited space of the intake air box, amplifying the air storage efficiency to the max.

››› Internal design

Combining three layers of mix density sponge, utilize the air filtration surface to the max resulting in excellent air intake efficiency.

››› High-performance filtration sponge

Choosing sponge as the air filter media, 3D construction design, combining 3 levels of sponge density, creating three-dimensional space to store dust. Rich sponge surface density allows sufficient clearance for air to travel in maintaining efficient intake filtration. All sponge is made in Germany.

››› Applying fluid mechanics design

All ARMASPEED ‘s products are engineered by the hydrodynamic design. To ensure our product to function at maximum capability, our design aims to achieve the highest efficiency in all areas.

››› Aluminum alloy frame construction

Constructed with an anodized aluminum frame to maximize the use of the 3D internal space and strengthen the durability. Ensuring the maximum usage of available space within the air intake box.

››› ISO 5011

All ARMA SPEED product is governed under ISO 5011, through testing in the controlled environment by giving a various level of filtration flow and dust, all data received is through analysis of this term as the final result. By data shown, ARMA product is able to achieve 94.9%-99.5% filtration rate. All design and testing purpose is to achieve in providing the product with great engine protection and joyful driving experience.

/wp-content/uploads/2019/09/ARMA-Speed-Drop-In-Air-Filter-D1.jpg

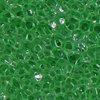

This shown a regular sponge, the foam wall is unprocessed. This type of sponge is constructed at low cost and the air filtration efficiency is poor, resulting to be a non-suitable material for an automotive air filter.

/wp-content/uploads/2019/09/ARMA-Speed-Drop-In-Air-Filter-D2.jpg

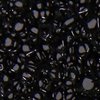

ARMA filter is treated through the network processing to remove the foam between the original mask and wall film sponge retaining the main body of the foam structure resulting in an excellent ventilation.

*Price quoted before GST

Call us now or visit our website for more information!

Website: http://www.fongkim.com.sg/

Facebook: https://www.facebook.com/fongkim.com.sg

Ad information

››› Appearance test

Maximized space utilization with 3D design. Tailored through each car, making full use of the limited space of the intake air box, amplifying the air storage efficiency to the max.

››› Internal design

Combining three layers of mix density sponge, utilize the air filtration surface to the max resulting in excellent air intake efficiency.

››› High-performance filtration sponge

Choosing sponge as the air filter media, 3D construction design, combining 3 levels of sponge density, creating three-dimensional space to store dust. Rich sponge surface density allows sufficient clearance for air to travel in maintaining efficient intake filtration. All sponge is made in Germany.

››› Applying fluid mechanics design

All ARMASPEED ‘s products are engineered by the hydrodynamic design. To ensure our product to function at maximum capability, our design aims to achieve the highest efficiency in all areas.

››› Aluminum alloy frame construction

Constructed with an anodized aluminum frame to maximize the use of the 3D internal space and strengthen the durability. Ensuring the maximum usage of available space within the air intake box.

››› ISO 5011

All ARMA SPEED product is governed under ISO 5011, through testing in the controlled environment by giving a various level of filtration flow and dust, all data received is through analysis of this term as the final result. By data shown, ARMA product is able to achieve 94.9%-99.5% filtration rate. All design and testing purpose is to achieve in providing the product with great engine protection and joyful driving experience.

/wp-content/uploads/2019/09/ARMA-Speed-Drop-In-Air-Filter-D1.jpg

This shown a regular sponge, the foam wall is unprocessed. This type of sponge is constructed at low cost and the air filtration efficiency is poor, resulting to be a non-suitable material for an automotive air filter.

/wp-content/uploads/2019/09/ARMA-Speed-Drop-In-Air-Filter-D2.jpg

ARMA filter is treated through the network processing to remove the foam between the original mask and wall film sponge retaining the main body of the foam structure resulting in an excellent ventilation.

*Price quoted before GST

Merchant information

Features & specs

››› Appearance

Maximized space utilization with 3D design. Tailored through each car, making full use of the limited space of the intake air box, amplifying the air storage efficiency to the max.

››› Internal design

Combining three layers of mix density sponge, utilize the air filtration surface to the max resulting in excellent air intake efficiency.

››› High-performance filtration sponge

Choosing sponge as the air filter media, 3D construction design, combining 3 levels of sponge density, creating three-dimensional space to store dust. Rich sponge surface density allows sufficient clearance for air to travel in maintaining efficient intake filtration. All sponge is made in Germany.

››› Applying fluid mechanics design

All ARMA Speed's products are engineered by the hydrodynamic design. To ensure our product to function at maximum capability, our design aims to achieve the highest efficiency in all areas.

››› Aluminum alloy frame construction

Constructed with an anodized aluminum frame to maximize the use of the 3D internal space and strengthen the durability. Ensuring the maximum usage of available space within the air intake box.

››› ISO 5011

All ARMA Speed product is governed under ISO 5011, through testing in the controlled environment by giving a various level of filtration flow and dust, all data received is through analysis of this term as the final result. By data shown, ARMA Speed product is able to achieve 94.9%-99.5% filtration rate. All design and testing purpose is to achieve in providing the product with great engine protection and joyful driving experience.

This shown a regular sponge, the foam wall is unprocessed. This type of sponge is constructed at low cost and the air filtration efficiency is poor, resulting to be a non-suitable material for an automotive air filter.

ARMA filter is treated through the network processing to remove the foam between the original mask and wall film sponge retaining the main body of the foam structure resulting in an excellent ventilation.

More items from this seller

& 2 Other Models

& 2 Other Models

Similar Items

Email Enquiry

* indicates compulsory field.